Lathe Spindle Nose Identification Chart

Review the diagrams below to determine your spindle nose type. Analyze the corresponding chart and make the required measurements. Select the spindle nose size for your chuck or adapter plate.

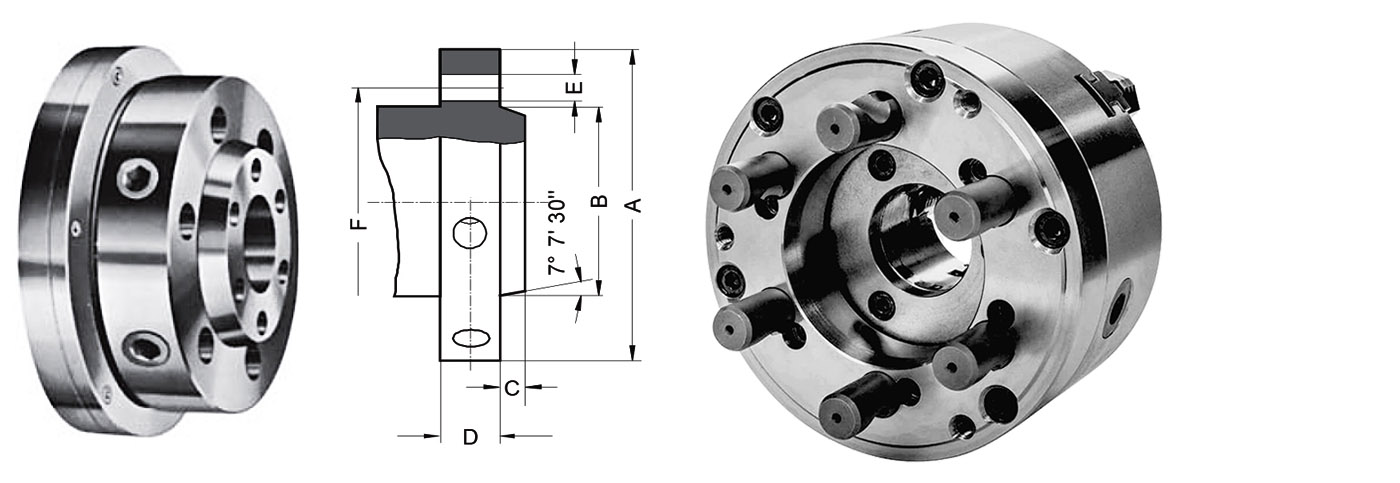

Type D - Camlock

Camlock pins are made with a D shape cutout on its body. They are used to mount a chuck to a lathe spindle.

D1-3 to D1-4 chucks and adapter plates have 3 camlock pins.

D1-5 to D1-15 chucks and adapter plates have 6 camlock pins.

To mount a chuck, a lathe operator inserts a chuck’s camlock pins into the lathe spindle, and using a wrench to rotate a cam inside the spindle, the operator pulls the camlock pins inward to snug the chuck tightly against the spindle.

| Spindle Nose Size | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| D1-3 | 92 | 53.983 | 11 | 32 | 3x15.1 | 70.6 |

| D1-4 | 117 | 63.521 | 11 | 34 | 3x16.7 | 82.6 |

| D1-5 | 146 | 82.573 | 13 | 38 | 6x19.8 | 104.8 |

| D1-6 | 181 | 106.385 | 14 | 45 | 6x23 | 133.4 |

| D1-8 | 225 | 139.731 | 16 | 50 | 6x26.2 | 171.4 |

| D1-11 | 298 | 196.883 | 18 | 60 | 6x31 | 235 |

| D1-15 | 403 | 285.791 | 19 | 70 | 6x35.7 | 330.2 |

| D1-20 | 546 | 412.795 | 21 | 82 | 6x42.1 | 463.6 |

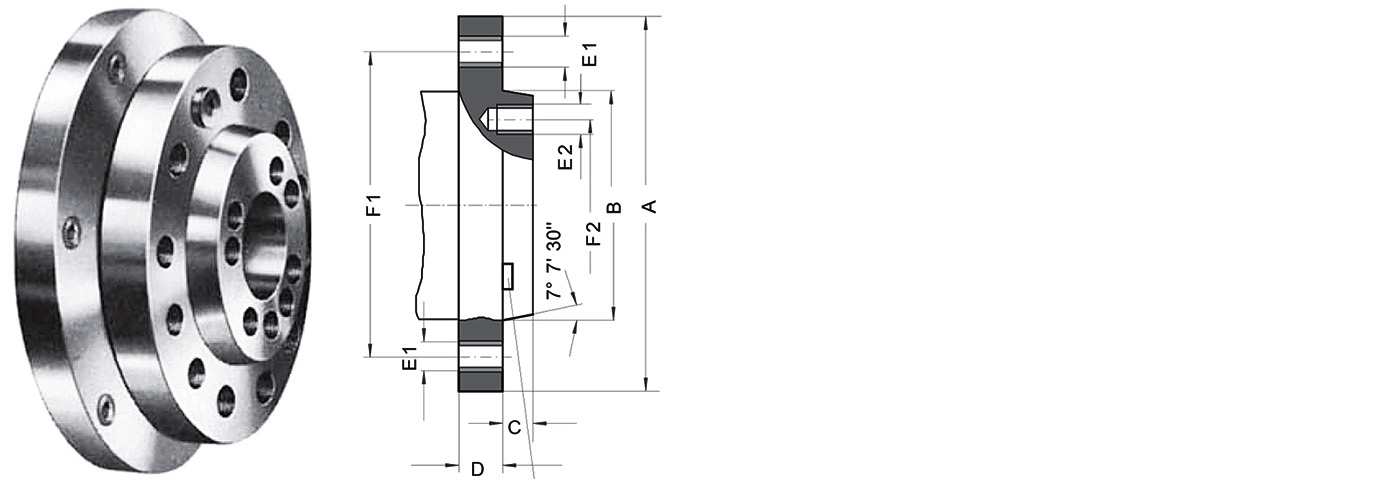

Type A1 - Short Taper

Tapped holes on outer-bolt circle and tapped holes on inner-bolt circle.

| Spindle Nose Size | A | B | C | D | E1 | F1 | E2 | F2 |

|---|---|---|---|---|---|---|---|---|

| A1-5 | 133.4 | 82.575 | 14.288 | 22.2 | 11x7/16-14 UNC | 104.8 | 8x7/16-14 UNC | 61.9 |

| A1-6 | 165.1 | 106.390 | 15.875 | 25.4 | 11x1/2-13 UNC | 133.4 | 8x1/2-13 UNC | 82.6 |

| A1-8 | 209.5 | 139.735 | 17.462 | 28.6 | 11x5/8-11 UNC | 171.4 | 8x5/8-11 UNC | 111.1 |

| A1-11 | 279.4 | 196.885 | 19.05 | 34.9 | 11x3/4-10 UNC | 235 | 8x3/4-10 UNC | 165.1 |

| A1-15 | 381 | 285.8 | 20.638 | 41.3 | 12x7/8-9 UNC | 330.2 | 11x7/8-9 UNC | 247.6 |

| A1-20 | 520 | 412.8 | 22.225 | 47.6 | 12x1-8 UNC | 463.6 | 11x1-8 UNC | 368.3 |

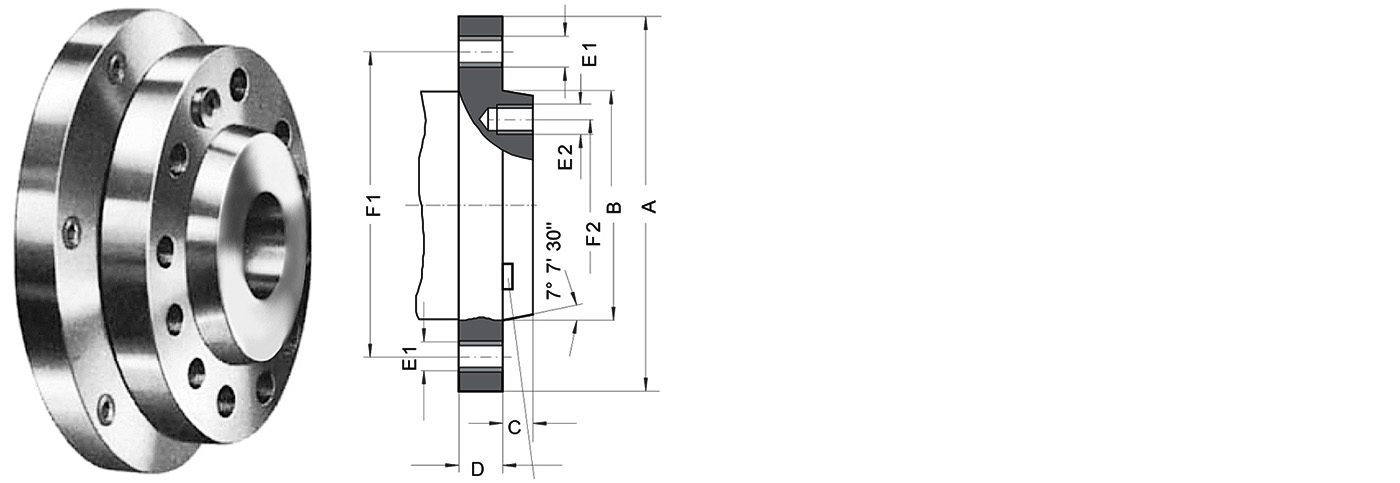

Type A2 - Short Taper

Tapped holes on outer-bolt circle, no holes on inner-bolt circle.

| Spindle Nose Size | A | B | C | D | E1 | F1 |

|---|---|---|---|---|---|---|

| A2-3 | 92.1 | 53.985 | 11.1 | 15.9 | 3x7/16-14 UNC | 70.66 |

| A2-4 | 108 | 63.525 | 11.1 | 19 | 11x7/16-14 UNC | 82.55 |

| A2-5 | 133.4 | 82.575 | 12.7 | 22.2 | 11x7/16-14 UNC | 104.8 |

| A2-6 | 165.1 | 106.390 | 14.3 | 25.4 | 11x1/2-13 UNC | 133.4 |

| A2-8 | 209.5 | 139.735 | 15.9 | 28.6 | 11x5/8-11 UNC | 171.4 |

| A2-11 | 279.4 | 196.885 | 17.5 | 34.9 | 11x3/4-10 UNC | 235 |

| A2-15 | 381 | 285.8 | 19 | 41.3 | 12x7/8-9 UNC | 330.2 |

| A2-20 | 520 | 412.8 | 20.6 | 47.6 | 12x1-8 UNC | 463.6 |

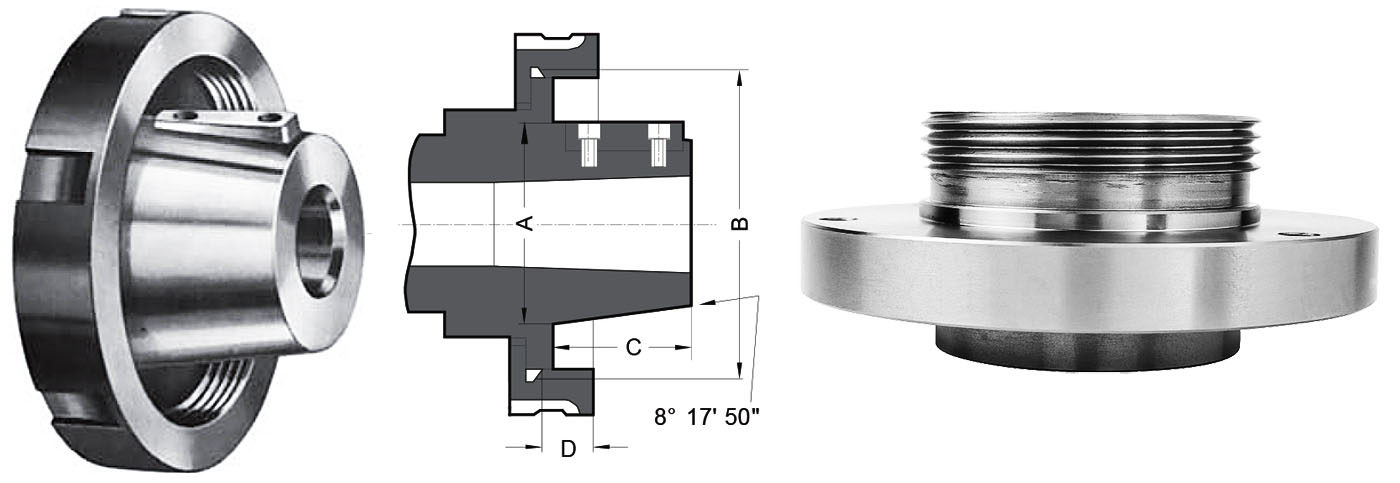

Type L - Long Taper

For centering and locating fittings, a key for positive location, and a flanged retention nut.

| Spindle Nose Size | A | B | C | D | Drive Key |

|---|---|---|---|---|---|

| L00 | 69.850 | 3 3/4-6 UNS | 50.800 | 14.288 | 9.525x38.1 |

| L0 | 82.550 | 4 1-2/-6 | 60.325 | 15.875 | 9.525x44.45 |

| L1 | 104.775 | 6-6 UNS | 73.025 | 19.050 | 15.875x60.32 |

| L2 | 133.350 | 7 3/4-5 UNS | 85.725 | 25.400 | 19.05x73.02 |

| L3 | 165.100 | 10 3/8-4 UNS | 94.425 | 28.575 | 25.4x82.55 |

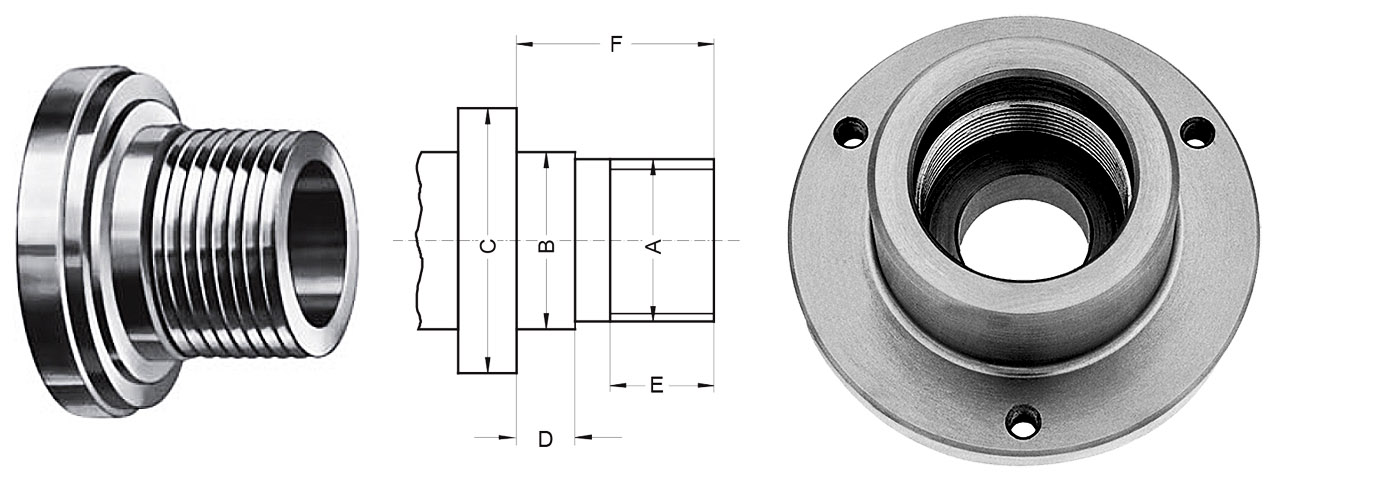

Threaded

| A | B | C | D | E | F |

|---|---|---|---|---|---|

| M 20 | 21 | 30 | 6.3 | 10 | 20 |

| M 24 | 25 | 36 | 8 | 12 | 24 |

| M 33 | 34 | 50 | 9 | 14 | 30 |

| M 39 | 40 | 56 | 10 | 16 | 35 |

| M 45 | 46 | 67 | 11 | 18 | 40 |

| M 52 | 55 | 80 | 12 | 20 | 45 |

| M 60 | 62 | 90 | 14 | 22 | 50 |

| M 76x6 | 78 | 112 | 16 | 30 | 63 |

| M 105x6 | 106 | 150 | 20 | 40 | 80 |